Peeling and cutting line for veneer

The veneer peeling and cutting line is designed for the production of peeled veneer from churaks of deciduous and coniferous breeds of wood. Equipment for the production of veneer has a capacity (depending on the grade of raw materials supplied for peeling) of about 3-5 m3/hour.

Veneer machines are designed for the production of peeled veneer with a length of 1300, 1650 mm, 2700 mm and a thickness of 0.5-3.6 mm. Veneer line maintenance rate: two operators per shift. Rotary cut veneer - veneer produced from birch, beech, oak, spruce, alder, aspen, pine and other wood species.

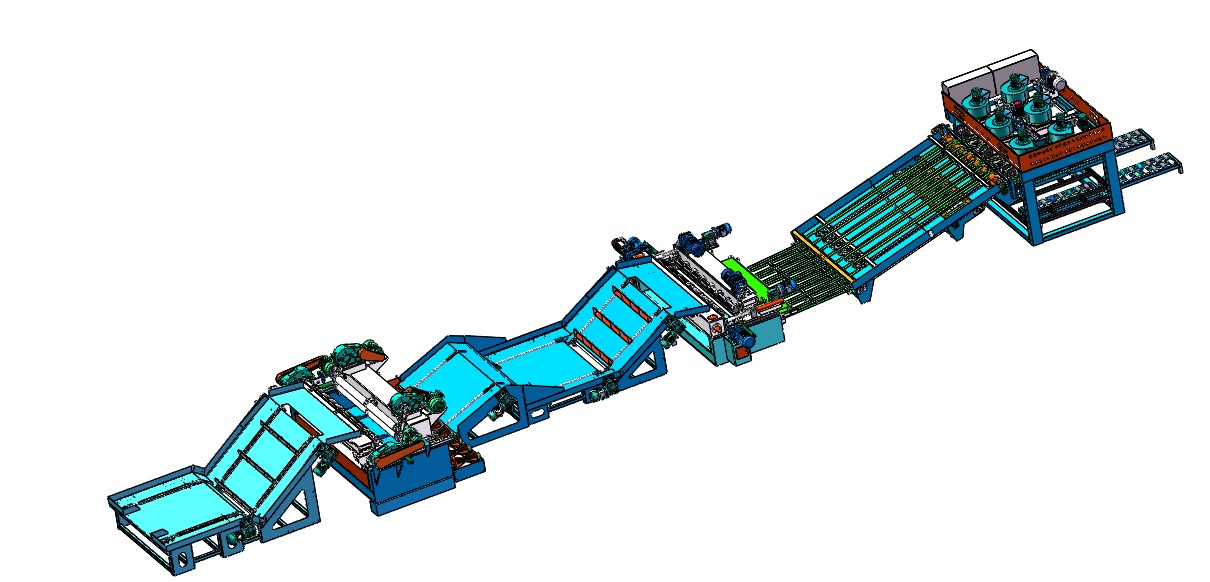

Veneer peeling equipment consists of the following mechanisms:

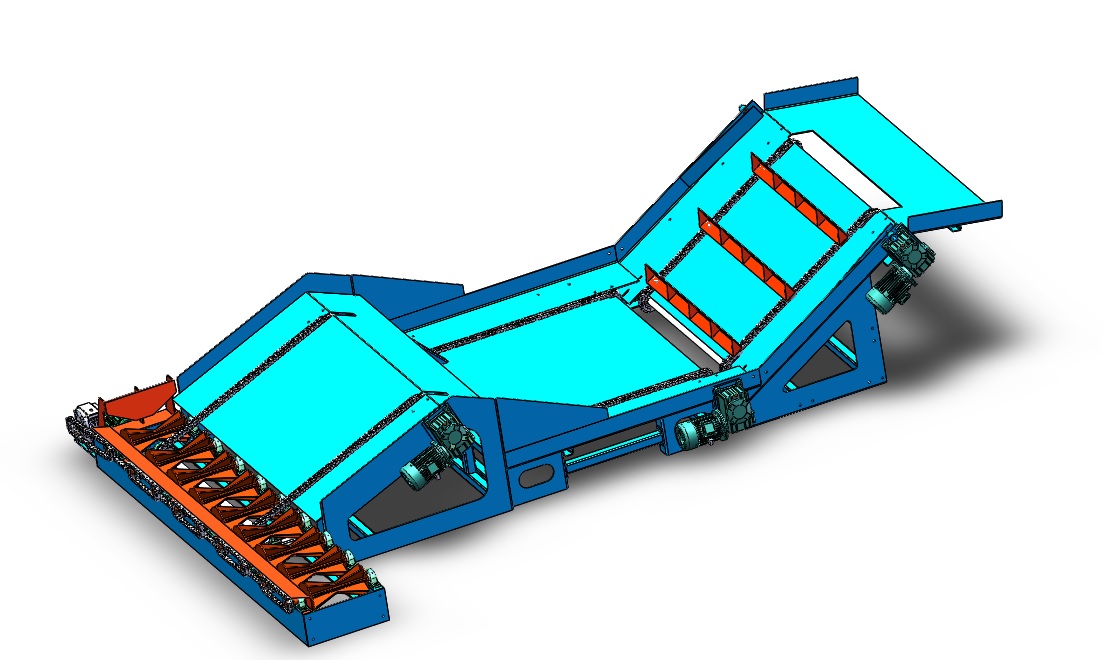

1. Loading conveyor.

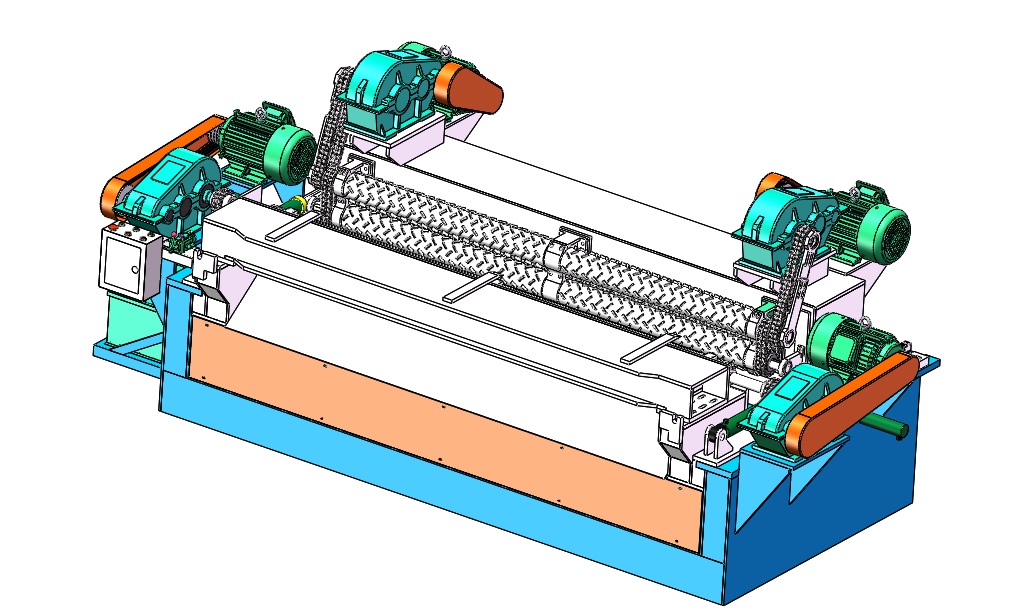

2. Debarking machine.

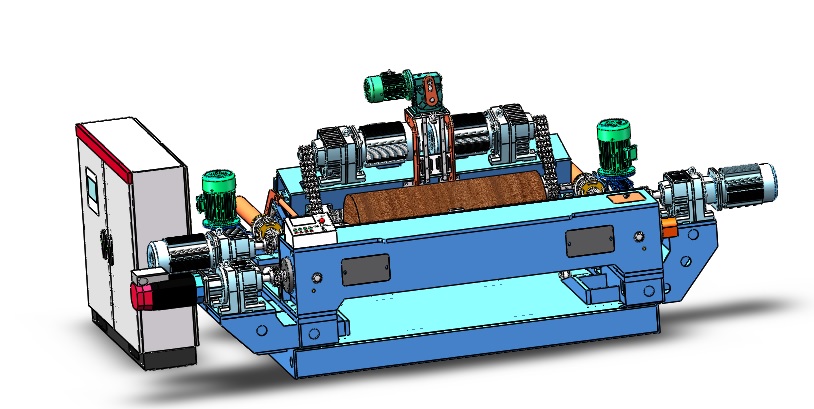

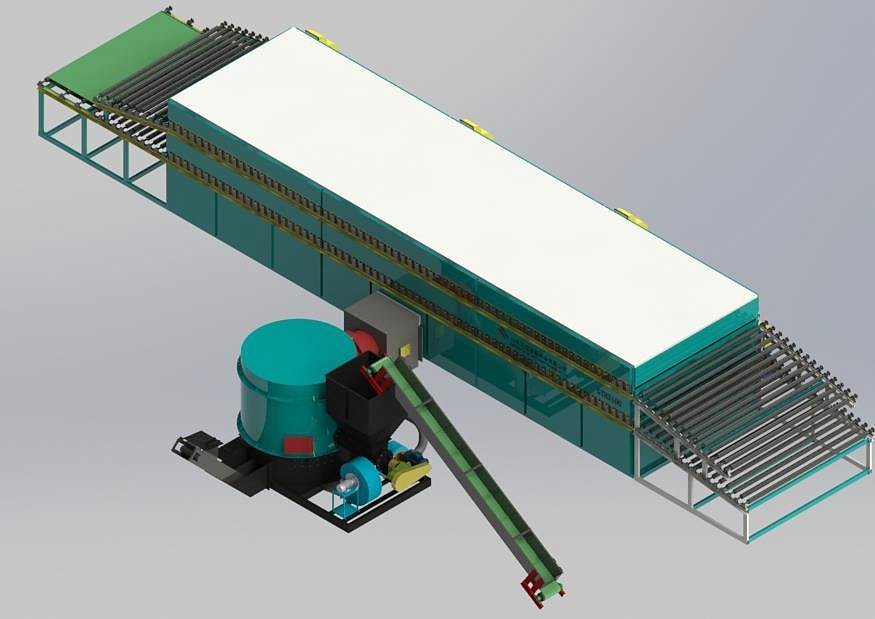

3. Feeding conveyor.

4. Peeling machine.

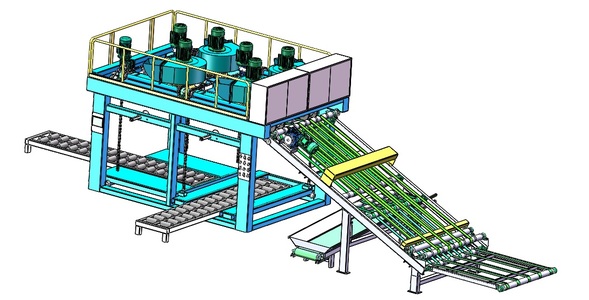

5. Veneer stacker (option).

6. Dryer for veneer (option).