Drying chamber for veneer using flue gases SHINE GTH30-32-2

Roller dryer GTH30-32-2(28+4 2-floors with boiler) is intended for drying plywood veneer.

The coolant in veneer dryers is hot air (thermal oil or steam is also suitable).

Number of floors:2.

Productivity: from 1.8–2.0 m3/hour.

Drying temperature: 130-190 ºС.

Veneer thickness: 0.8–8 mm.

Final moisture content of veneer: 10 ± 2%.

We can also produce products according to individual customer orders (especially for cold regions). Welcome to contact us for a consultation.

Purpose

The roller veneer dryer is designed for drying veneer with a thickness of 0.8 to 8 mm.

Application area

This veneer dryer is used in wood processing plants and plywood factories of all capacities that produce veneer and plywood.

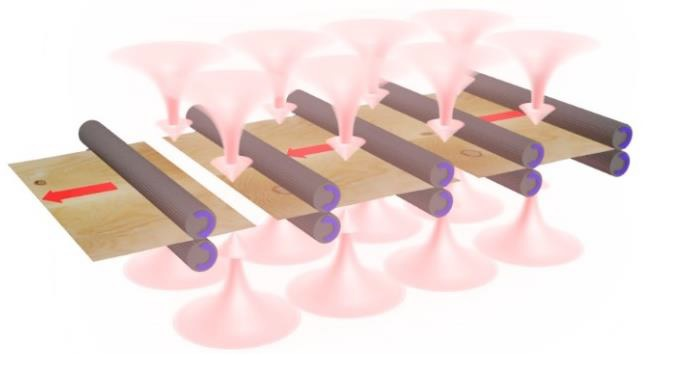

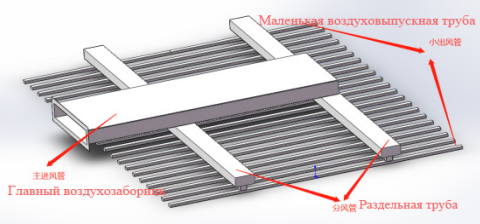

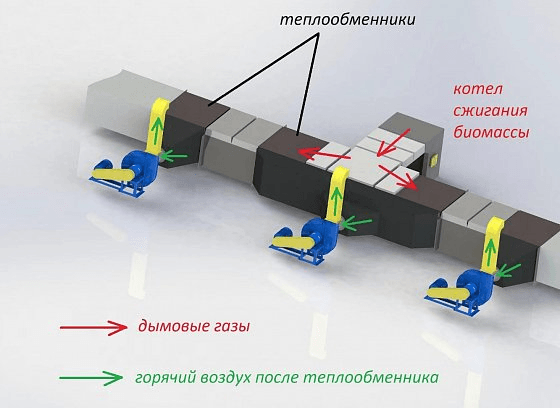

The veneer passes through the machines longitudinally and is compressed by upper and lower drive rollers. Streams of hot air from boxes with nozzle blast are directed onto the veneer from above and below. The built-in boiler in the dryer burns sawdust (biomass), and the resulting heat is transferred to the dryer through a heat exchanger.

Processing scheme

Design features

Heat exchanger

Flue gases enter the dryer through a heat exchanger, which eliminates the appearance of soot and smoke on the veneer and inside the dryer, thereby ensuring the cleanliness of the veneer.

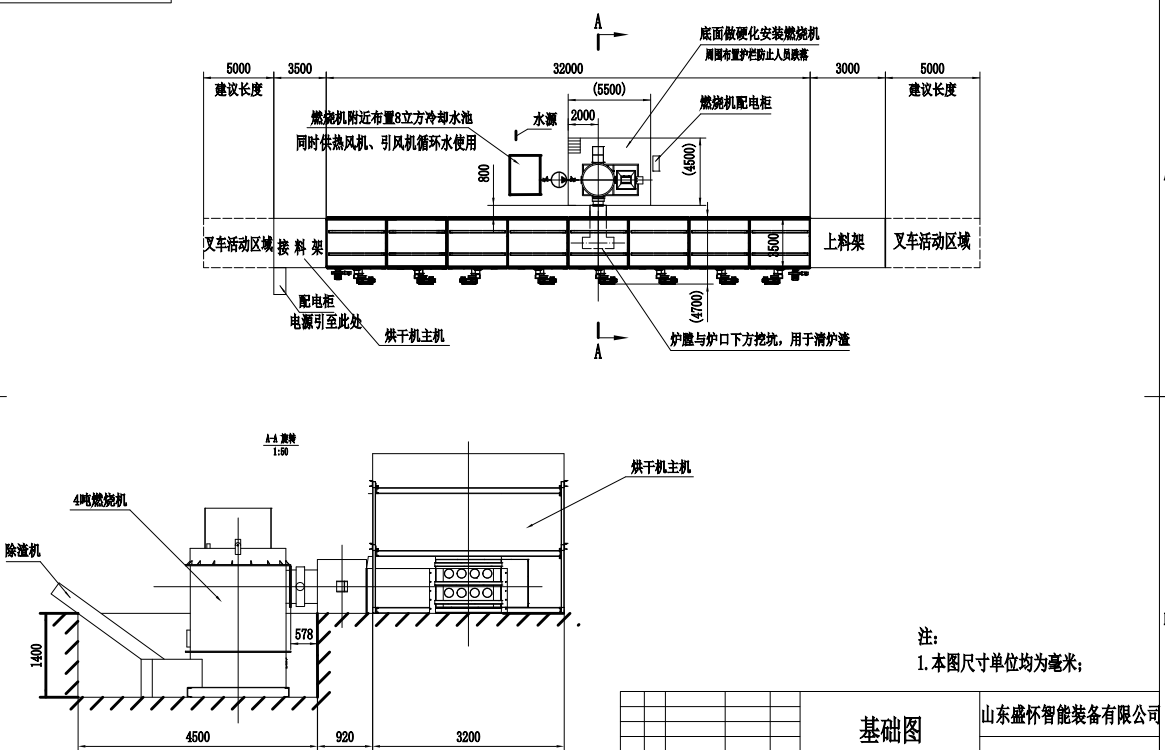

Equipment foundation diagram

Specifications

Model No. |

GTH30-32-2 |

Working width |

3000mm |

Number of floors |

2 |

Roller material |

Q235B, φ89 steel pipe |

Heating zones |

28m |

Cooling zone |

4m |

Veneer thickness |

0.8-8mm |

Final humidity |

Fresh key up to about 10% |

Heating material and drying temperature |

Waste wood, adjustable from 140 to 190℃. There is an automatic temperature control and speed adjustment system, which can guarantee the same moisture content. |

Drying capacity (m³/h) |

1.8-2.0 cubic meter |

Feed rate |

5-22m/min,16A circuit |

Hot air fan power |

5.5kW(7pcs) |

Conveyor power |

5.5kW,frequency regulation(2pcs) |

Cooling fan power |

5.5kW(1pcs) |

Exhaust fan power |

7.5kW(2pcs) |

Power of 4 ton boiler |

16.5kW |

general power |

86.5kW |

Actual electricity consumption |

Approximately 56 kW per hour |

Coverage area approx. |

38 X 9 X 2.95m |

Electrical components |

Chinese brand or Schneide |

PLC |

Chinese brand or Mitsubishi |

Dried veneer

ABOUT US

"Shandong Shine Machinery" is located in Shandong Province, China. She has specialized in the production of veneer dryer for more than 20 years and is the vice president of Shandong Wood Processing Association. Our customers span more than 40 countries and regions around the world, and our technology has received recognition from customers both domestically and internationally. We regularly participate in professional exhibitions both in China and abroad, and have representatives in several countries. We welcome clients from all over the world to visit us.

Our services

Pre-sales services:

1. Free consultation on all types of equipment for plywood production.

2.Offering reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to visit our factory.

Services during sales:

1.Inspection of the machine before shipment from the factory.

2. Installation and configuration of equipment abroad.

3.Training of first line operators.

After sales services:

1.24-hour online service.

2.Providing videos with installation and configuration of equipment.

3.Providing technical support (Technical phone: +8619653165764). Possibility of providing on-site services to the client.