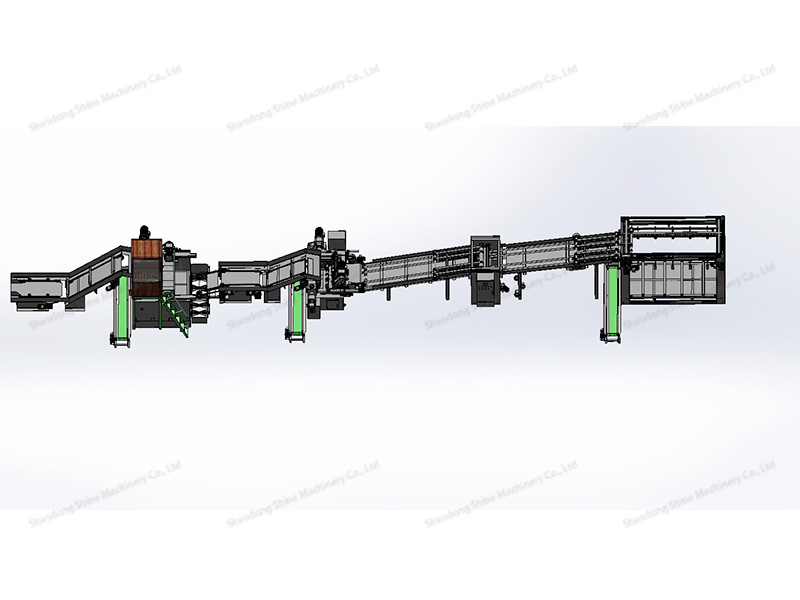

Veneer making equipment

Veneer making equipment

Veneer is a thin sheet of wood obtained by rotary cutting, slicing or peeling a log. Veneer is used in furniture and decor, but it is mainly the main ingredient in the production of plywood and LVL. If the quality of the wood veneer is very good, then the final product, such as plywood or furniture, will be of high quality, which will be very beneficial for your business.

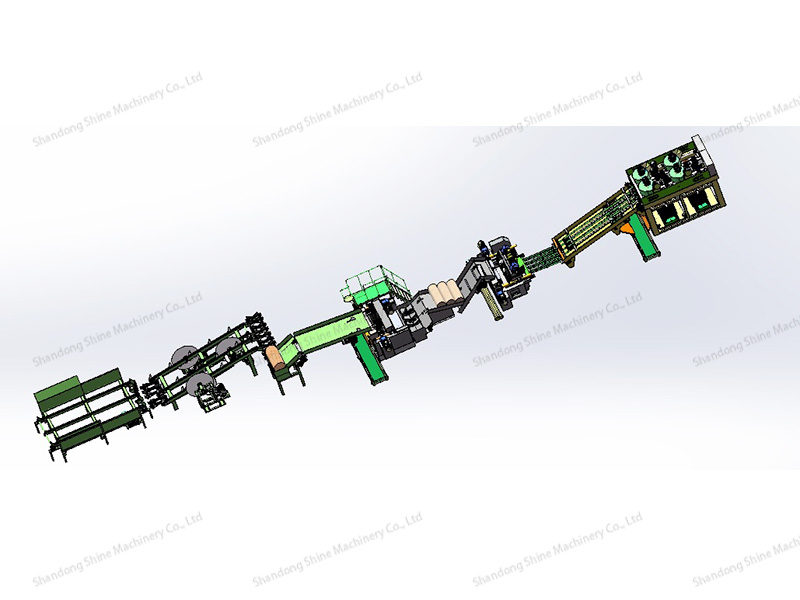

The production of veneer consists of several phases, from processing and cleaning logs to drying and gluing the resulting veneer. Each phase requires its own specialized equipment. We improve every stage of production, both technologically and procedurally, in order to create the most optimal veneer. Our machines can produce veneers from all types of wood.

Shine supplies lines and machines for veneer production. We know the most important points of each phase of the process, from processing logs to obtaining a high-quality end product. With us, your veneer production process starts with the most accurate and efficient log processing on the market.

The veneer peeling machine is a necessary equipment for the production of wood veneer. The principle of operation of the veneer peeling machine is that when the log rotates under the action of the engine, the log is processed and turned into wood veneer sheets.

First: Softening logs:

Before the peeling process, if your tree is very hard, it is best to place the log in water to cut it into smooth sheets of uniform thickness.

Second: Wood debarker / log debarker:

The function of a tree debarker is to process the tree to remove the bark and give it a round shape. The tree debarker is easy to operate, its structure is simple, through the forward and backward movement of the hydraulic cylinder, debarking work is carried out.

Third: Veneer Peeling Machine / Veneer Lathe:

Spindleless veneer peeling machine consists of machine frame, rollers, motors, electrical box, cnc screen. Through setting the veneer thickness and width through cnc screen, then place the log and press the start button, the veneer machine will automatically work. As the peeling of wood occurs by rotating against the knife, it is peeled into a veneer.

Various veneer peeling machines, various configurations.

If the veneer peeling machine is for soft woods such as poplar, then the configuration of the machine is normal and does not require high power, and the power of the veneer peeling machine should not be too large, because soft woods are easier to process.

But if your log is hardwood such as beech, birch, acacia, then the veneer peeling machine is required to be powerful enough, more powerful and heavy to keep the veneer thickness accurate and balanced.

And the speed, thickness range, structure and other characteristics of the veneer peeling machine will be different.

The standard size of the veneer peeling machine is 4ft (maximum log length 1300mm) and 8ft (maximum log length 2600mm), also can be customized according to your conditions.