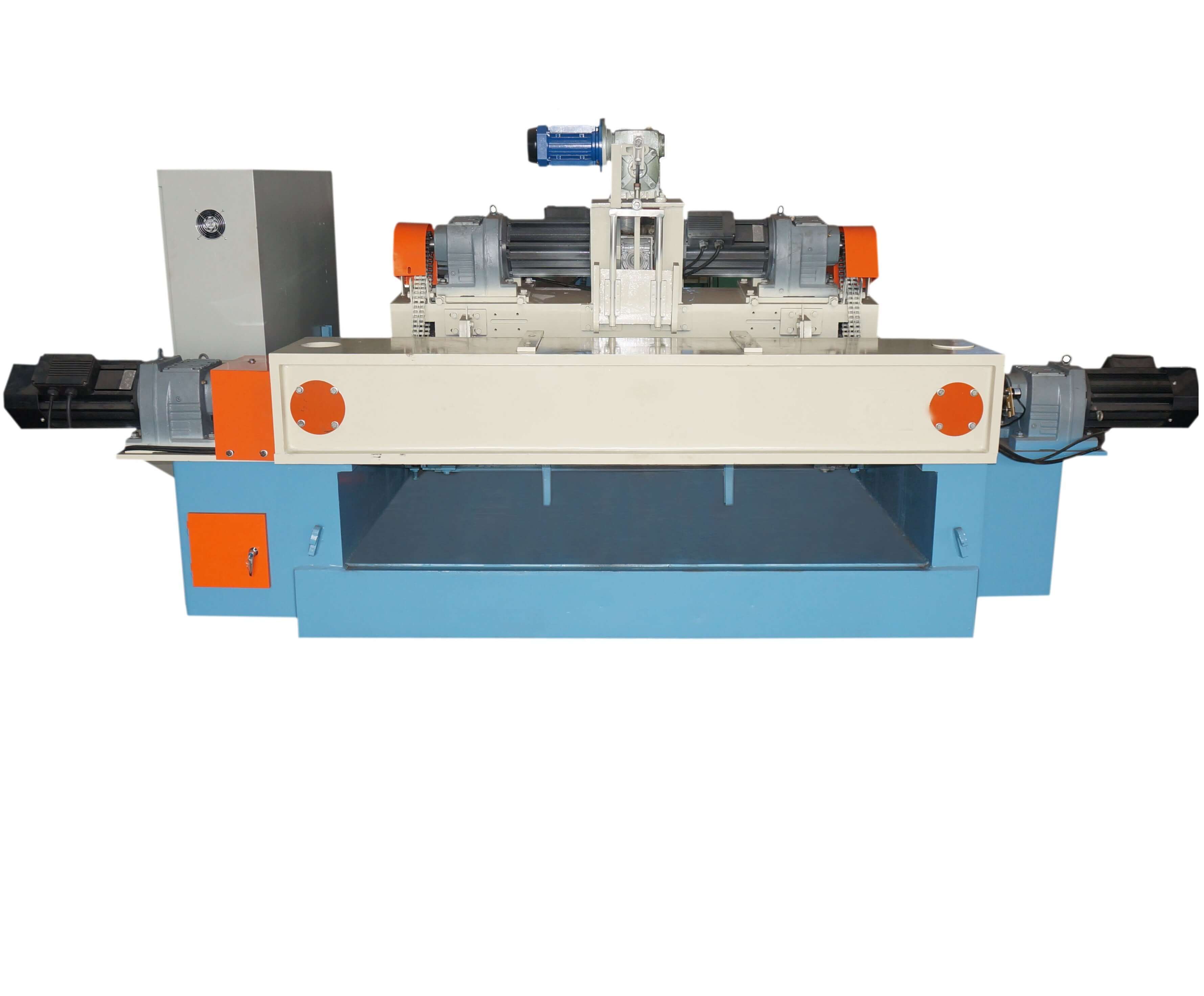

4ft Peeling Machine for Peeling and Cutting Veneer

The blade case has a fixed base, and two-wheeled rollers provide its movement and stabilize the guide. This improves stability and quality of material processing, and also facilitates movement.

The equipment catalog presents various modifications of peeling machines for the production of veneer and plywood, including spindleless and spindle machines, which are equipped with a CNC control system, hydraulic spindles and auto-loading. The diameter of the “pencil” at the outlet can be 24 mm, 28 mm or 32 mm.

The operating principle of the peeling machine in the peeling line for veneer production is as follows. The raw material is first steamed to make it more flexible. The log is then fed to a debarker where bark, dirt and sand are removed. After this, the ridge is cut into blocks of a certain length, then it is cylindered. Then, using movable knives, the veneer strip is peeled and cut into strips.

The peeling machine was invented at the end of the 19th century. Without this equipment today it is simply impossible to imagine the production of plywood and the manufacture of matches. Over the past hundred-plus years, many designs and modifications of machines have been created, but the principle has remained the same: cutting a thin strip of wood from short logs.

But with many advantages, traditional peeling machines also have serious design disadvantages associated with the need to use cams that stick into the ends of the blocks and force them to rotate. Often the block turns in the fists and further peeling becomes impossible. As a rule, this occurs due to heart rot, which is especially common in aspen logs. As a result, the so-called screws are obtained - blocks of large diameter, unsuitable for further processing on a peeling machine.

Options

Designation |

Unit |

Parameter |

Main and auxiliary engine power |

kW |

Double roller main motor electric 11 kW*2 Host single roller motor 11 kW*2 Feed motor Servo motor 15 kW Hob motor 4kW servo drive 2.2 kW rubber roller transmission motor |

Maximum log length |

mm |

970-1270 |

Maximum log diameter |

mm |

Max. 600 mm - wood core 80 mm |

Veneer withdrawal speed |

m/min |

40-80 |

Veneer thickness |

mm |

2-8 |

Dimensions |

mm |

(L)5000*(W)2400*(H)1600 |

Total weight |

kg |

7200 |

Certification

Zavod Shine

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After-sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.