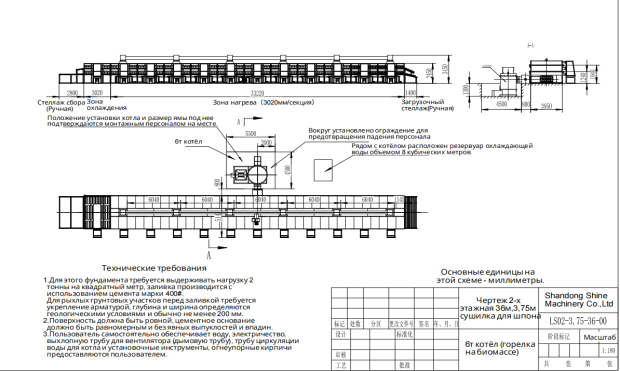

Veneer dryer 2-level 36m with six-ton burner

Environmental sustainability: Biomass combustion is an environmentally friendly and energy efficient process. Using a biomass burner helps reduce emissions of harmful substances and reduce the negative impact on the environment.

Cost-effective: Using biomass as a fuel source for the dryer reduces energy costs. Biomass is generally available at lower prices than other fuels, which helps reduce production costs.

Veneer dryer 2-level 36m with six-ton burner installed in Russia. This dryer model was made specifically for the needs of Russian customers. The dryer produces about 50-60 cubic meters of boards per day. The thermal configuration of the dryer is a biomass burner.

Specifications

Model no |

GTH375-36 |

Working width |

3750 mm |

Number of floors |

2 |

Roller material |

Q235B, φ89 steel pipe |

Heating zones |

32 m |

Cooling zone |

4 m |

Veneer thickness |

0.6-8 mm |

Final humidity |

Fresh key up to about 10% |

Heating material and drying temperature |

Waste wood, adjustable from 140 to 200℃. There is an automatic temperature control and speed adjustment system, which can guarantee the same moisture content. |

Drying capacity (m³/h) |

3 cubic meter |

Feed rate |

5-22m/min,16A circuit |

Heating fans power |

5.5kW (11 units) |

Conveyor power |

5.5kW,frequency regulation(2pcs) |

Cooling fan power |

5.5kW (1 pc.) |

Power exhaust fan |

7.5 kW (2 pcs.) |

Power 6-ton boiler |

20 kW |

general power |

112 kW |

Actual electricity consumption |

Approximately 73 kW per hour |

Coverage area approx. |

42 m X 10 m X3m |

Electrical components |

Cut |

PLC |

Mitsubishi |

Biomass burner

The six-ton biomass burner is a burning machine that produces up to 3.6 MILLION calories per hour

Biomass burner is a special invention of Shine Machinery Co., Ltd in China, which can burn various wood waste directly. This allows you to significantly reduce fuel and drying costs. Unlike steam or thermal oil dryers, there is no need for a steam boiler, gas, coal or oil. Drying occurs very efficiently, with low fuel consumption, which leads to energy and cost savings. Using a biomass burner not only reduces costs, but also ensures ideal drying results.

The biggest advantage of our company's burners is the diversification of fuel types. Depending on the season and time, the cheapest fuel is selected, thereby reducing the customer's production costs without worrying about increasing production costs due to changes in fuel prices.

The advantages of the design are:

1. Rotating Grate: This ensures that the fuel is completely and evenly distributed throughout the grate and burns completely.

2. Built-in circulating water cooling: ensures long service life of the burner and no problems during long-term operation.

3. Wet wood with a moisture content of more than 40% can also be completely burned.

4. Slag removal and combustion air supply systems are sealed with water.

5. The air supply fan, supply motor, grill rotation system and air distribution fan are controlled by frequency converter, which ensures sufficient heat supply without wasting fuel.

6. All parts of the furnace that come into contact with the fire are cast from castings that can withstand high temperatures of 1700 degrees Celsius.

Benefits of using a biomass burner

Renewable Energy: Biomass is a renewable energy source because it comes from plant resources that can be recycled and grown again.

Reduced Greenhouse Gas Emissions: Burning biomass in a burner does not add more greenhouse gases to the atmosphere because the burnt gases released do not cause negative climate impacts when properly cleaned.

Cost-effective: Biomass is often available in large quantities and at low cost or even free. Therefore, using a biomass burner can be cost-effective in terms of reducing fuel and energy costs.

Organic waste disposal: Using biomass in the burner helps eliminate organic waste that could otherwise lead to pollution or negative environmental impacts. The burner can burn the waste that is generated in the veneer production line, preventing the accumulation of debris.

The SHINE heat exchanger operates on the basis of step-by-step heat transfer, with each section of this exchanger having its own unique characteristics. Thus, hot air is evenly distributed over the entire surface of the veneer. As a result, the veneer has a uniform moisture content, an even structure, no kinks or waviness at the ends, and no layers, which provides good conditions for gluing.

Shine veneer dryer adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve perfect drying effect.

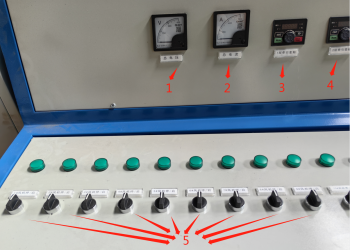

Dryer control cabinet

1. General voltmeter

2. General ammeter

3. Ground floor traction frequency conversion

4. Second-story traction frequency conversion

5. Fan №XX off/on

6. Temperature regulator

7. Starting Main Control

8. Emergency switch

Burner control cabinet

1. Fan frequency conversion

2. Feeder frequency conversion

3. Grid Machine Frequency Conversion

4. Blower off/on

5. Forward/reverse rotation feeder

6. Forward/reverse rotation screen machine

7. Conveyor off/on

8. Circulation pump off/on

9. Cooler off/on.

10. Slag removal device off/on

11.Emergency switch

12.Heating automatic/manual

13.Overheat alarm

14.Temperature control zone

15.Start main control

Certification

Company qualification: Shine veneer dryer has full qualifications and certificates, including ISO9001 quality management system certification and CE certification. These certificates demonstrate our company's high standards in terms of product quality, manufacturing processes and services.

Commercial terms :

1. Packaging and Transportation: Items will be shipped by export packages. During sea or rail transportation, as well as other modes of transport to the destination, the packaging must be able to protect the cargo from any damage and corrosion.

2. Quality Guarantee: All machines, except normal wear parts, are covered by a one-year warranty. After the warranty period expires, the seller will offer wear parts at a competitive price.

3. Payment terms: T/T with 30% as deposit and full balance paid before delivery.

4. Delivery time: After receiving the deposit, we will start production and the product will be ready in within approximately 30 working days . After the client checks the goods and pays the balance of 70% of the total contract value, we will deliver the goods at the time agreed upon by both parties.

5. Offer validity: one month

6. Installation and commissioning

We will send videos and drawings for installation guidance. If the covid19 situation allows, the seller can also send an engineer to the destination country to guide the installation and debugging, at the same time, our engineers are responsible for training the buyer's operators; The buyer should be responsible for our engineers' round trip airfare, visa costs, food and accommodation, and personal safety. And the buyer must supply one Chinese translator for our engineers. And the buyer must pay a salary of 100 US dollars per day to our engineer.

7. Our products are constantly updated, if there is any data discrepancy, please refer to the actual product.

Client case

Shine has established long-term and stable cooperative relationships with customers all over the world. Our veneer dryers are widely used in furniture manufacturing, woodworking, building materials and other industries.

This is a case study of our products.

Thailand GTH30-48 2-storey veneer roller dryer

Ivory Coast GTH30-44 2-storey veneer roller dryer

Zavod Shine

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.