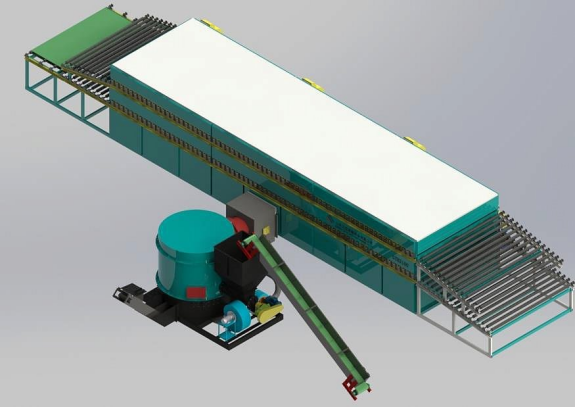

2-story veneer dryer in Russia

Patented moist air exhaust system designed specifically for users in cold northern regions. It can be separately retrofitted to any of our dryer models for veneer.

The moisture drainage device is installed on the top of the dryer, which allows the moisture inside the dryer to be discharged to the outside in a timely and quick manner, avoiding cold steam condensation caused by the temperature difference between the inside and outside of the dryer, and maintaining the balance of dryness and pressure inside the dryer.

The veneer dryer produced by Shandong Shine Machinery Co., Ltd is widely used for leveling drying of high quality plywood, sandwich panels and architectural veneer surfaces. It is equipped with environmentally friendly hot air oven type. Its characteristics: fuel economy, double use of hot air, increased heating speed. After drying, the veneer becomes smooth, the moisture content meets state standards. Equipped with one-piece high-efficiency and energy-saving hot air furnace type. Without boiler and other auxiliary equipment, without using water, coal, electricity. Bark, sawdust and wood waste can be used as fuel and can quickly reach the required heat for the dryer.

A 2-story roller dryer for veneer was installed in Russia in December 2023.

Specifications

Model no |

GTH375-36 |

Working width |

3750 mm |

Number of floors |

2 |

Materia rolikov |

Q235B, φ89 steel pipe |

Heating zones |

32 m |

Cooling zone |

4 m |

Veneer thickness |

0.6-8 mm |

Final humidity |

Fresh key up to about 10% |

Heating material and drying temperature |

Waste wood, adjustable from 140 to 200℃. There is an automatic temperature control and speed adjustment system, which can guarantee the same moisture content. |

Drying capacity (m³/h) |

3 cubic meter |

Feed rate |

5-22m/min,16A circuit |

Heating fans power |

5.5kW (11 units) |

Conveyor power |

5.5kW,frequency regulation(2pcs) |

Cooling fan power |

5.5kW (1 pc.) |

Power exhaust fan |

7.5 kW (2 pcs.) |

Power 6-ton boiler |

20 kW |

general power |

112 kW |

Actual electricity consumption |

Approximately 73 kW per hour |

Coverage area approx. |

42 m X 10 m X3m |

Electrical components |

Cut |

PLC |

Mitsubishi |

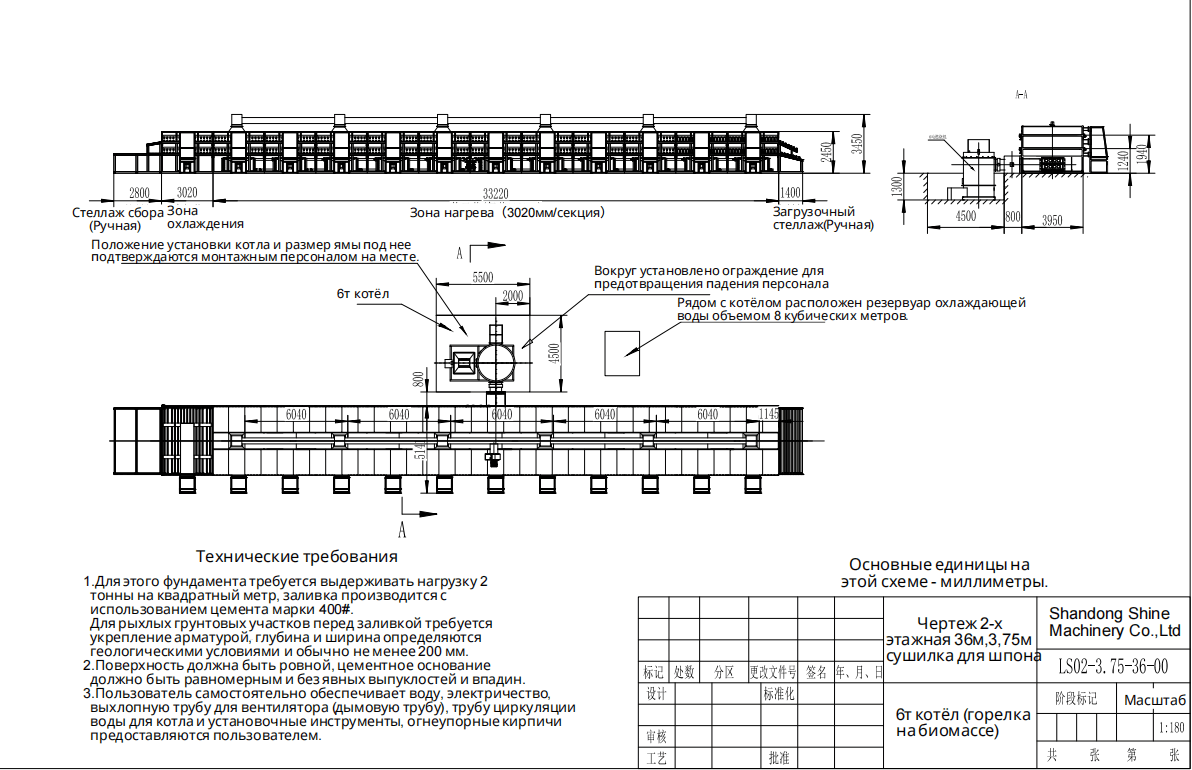

Drawing _ equipment

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After-sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.