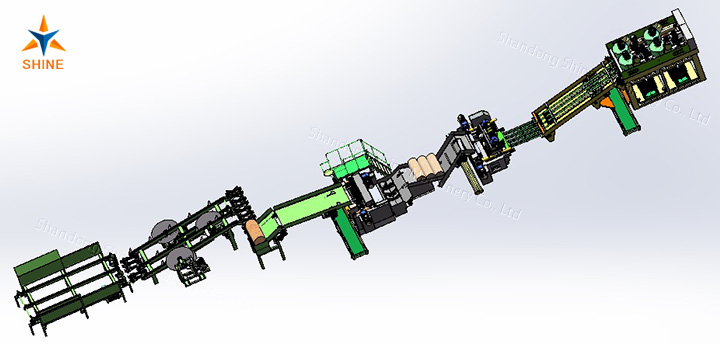

Rotary Lathe for Veneer/Plywood Production Line

The 4ft and 8ft spindleless veneer peeling and cutting production line is another automatic production process. In plywood production, this line consists of log feeding device, log debarking machine, veneer peeling lathe, automatic stacker, overall only two workers are required, time saving, high efficiency.

Spindleless veneer peeling machine is one of the plywood production equipment, which belongs to the mechanical spindleless rotary cutting transmission, suitable for lathe cutting the remaining core wood to continue into veneer, also can be applied to small diameter wood (diameter 300mm) into veneer. These advantages are:

1. Processing uniform board thickness, smooth surface;

2, reasonable structure, easy to operate and maintain;

3, equipment performance is stable, fewer wearing parts, long service life;

4, saving forest resources.

5. Artificial technical requirements are low, with normal peeling machine, the error is ±0.1mm.

| Maximum length | 1300 mm |

| Max diameter | 500 mm |

| Mini residual log diameter | 28 mm |

| Veneer thickness | 0.5 - 3.6 mm |

| Cleaning speed | 45 - 65 m/min |

| Power | 21.5 kW |

| dimensions | 2800*2100*1350 mm |

| Weight | about 3500 kg |

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764 ). A visit to the client service is available.