Roller dryer for veneer 2-story 30m

Working width:3m

Productivity:1.8-2m³/h

Heating zones:28m

Cooling zone:2m

Advantages of roller dryers for veneer.

Uniform Drying: This type of roller dryer ensures even heat distribution across the surface of the plywood, ensuring a uniform and consistent drying process, eliminating the problem of over-drying or uneven drying.

High efficiency and productivity: The plywood roller dryer usually has a large drying surface, which allows it to process large quantities of plywood at the same time. Its highly efficient design helps increase productivity, shorten production cycles and increase yield.

Adjustable Drying Parameters: Typically, this type of drying equipment has adjustable parameters such as heat, roller speed and drying time, allowing operators to precisely control the process depending on the material and thickness of the plywood, meeting different drying requirements.

Wide Range of Applications: The plywood roller drying machine is suitable for various types of plywood materials, such as plywood sheets, chipboard and others. Its versatility makes it an ideal choice for drying plywood in the woodworking industry, providing high adaptability.

Veneer dryer parameters

| Model | 26+4 2 floors with boiler Width 3.0m |

| Working width | 3 m |

| Dryer temperature, ℃ | 140-200 |

| Roller material | Steel pipe Q235B, φ89 |

| Heating zones | 28 m |

| Cooling zone | 2 m |

| Initial humidity | 60-80% |

| Final humidity | 10% +/-2 |

| Performance | 1.8-2m³/h |

| Feed rate | 5-22m/min |

| Heating fans power | 5.5kW*7 |

| Cooling fan power | 5.5kW*1 |

| Conveyor power | 5.5kW*2 |

| Exhaust fan | 7.5kW*1 |

| general power | 62.5 kW |

| Electricity consumption | 41 kW/h |

| Wood chip consumption | 6-7 tons/day |

| Number of staff | 5-7 people/cm |

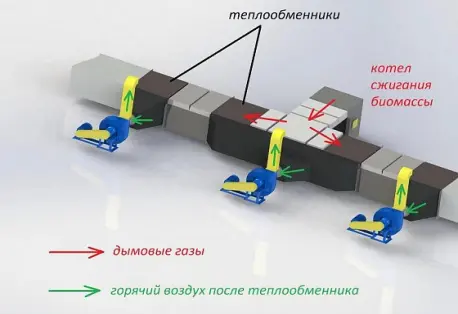

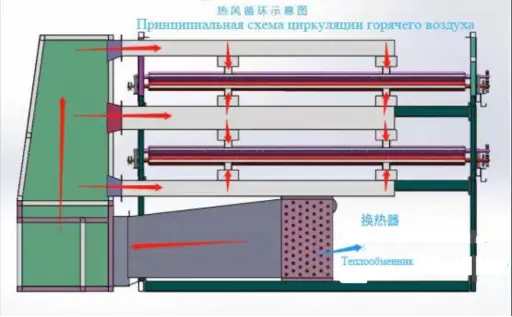

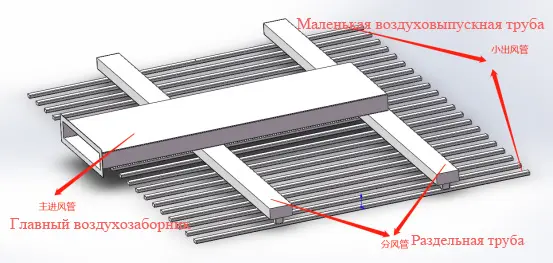

Principle of operation

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764 ). A visit to the client service is available.