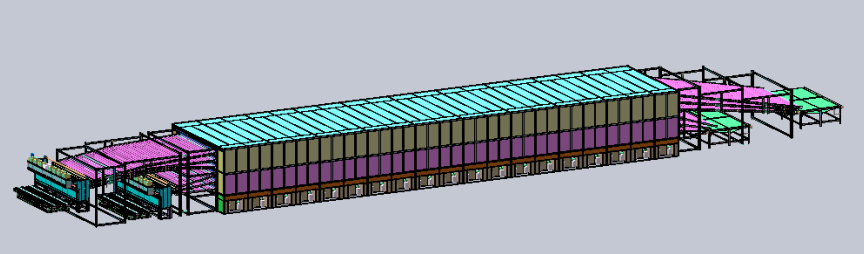

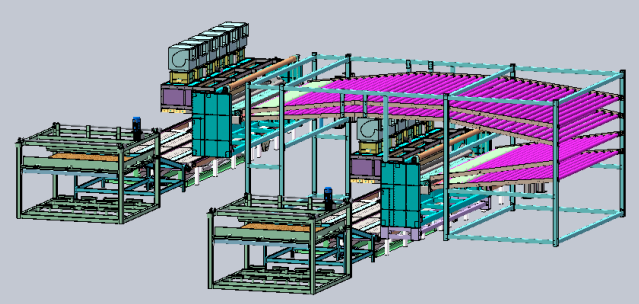

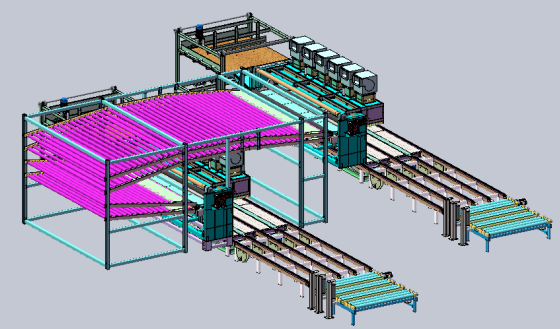

Roller dryer for veneer 6-storey 42 meters GTH612-42

The 6-story veneer roller dryer is a new equipment developed in 2024, designed for high-performance work.

Number of floors: 6.

Productivity: from 15–18 m3/hour.

Drying temperature: 160-180 ºС.

Veneer thickness: 0.8–8 mm.

Final moisture content of veneer: 10 ± 2%.

We can also produce products according to individual customer orders (especially for cold regions). Welcome to contact us for a consultation.

Specifications

Model No. |

GTH612-42 |

Working width |

6000mm |

Number of floors |

6 |

Roller material |

Q235B, φ115 steel pipe |

Heating zones |

38m |

Cooling zone |

4m |

Veneer thickness |

0.8-8mm |

Final humidity |

Fresh key up to about 10% |

Drying temperature |

160-180 ºС |

Drying capacity (m³/h) |

15-18 cubic meter |

Feed rate |

5-22m/min,16A circuit |

Hot air fan power |

15kW(36pcs) |

Conveyor power |

7.5kW,frequency regulation(6pcs) |

Cooling fan power |

15kW(4pcs) |

general power |

119.5kW |

Actual electricity consumption |

Approximately 78 kW per hour |

Coverage area approx. |

65 X 9 X 5.5m |

Electrical components |

Chinese brand or Schneide |

PLC |

Chinese brandor Mitsubishi |

Who are we?

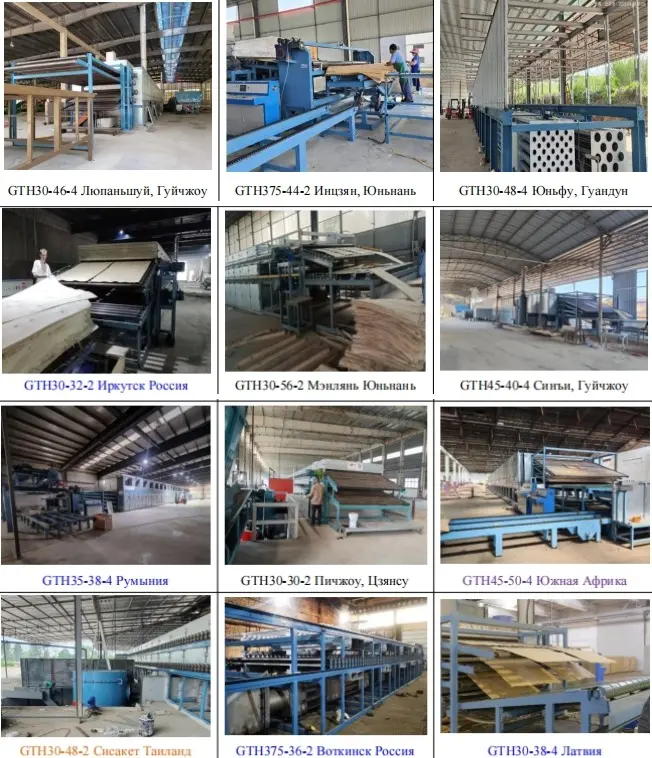

"Shandong Shine Machinery" is located in Shandong Province, China. It has specialized in the production of veneer dryer for more than 20 years and is the vice president of Shandong Wood Processing Association. Our customers cover more than 40 countries and regions around the world, and our technology has been recognized by customers both domestically and and beyond. We regularly participate in professional exhibitions both in China and abroad, and we have representatives in several countries. We welcome customers from all over the world to visit us.

Commercial terms

1. Packaging and Transportation: Items will be shipped by export packages. During sea or rail transportation, as well as other modes of transport to the destination, the packaging must be able to protect the cargo from any damage and corrosion.

2. Quality Guarantee: All machines, except normal wear parts, are covered by a one-year warranty. After the warranty period expires, the seller will offer wear parts at a competitive price.

3. Payment terms: T/T with 30% as deposit and full balance paid before delivery.

4. Delivery Time: After receiving the deposit, we will start production and the product will be ready within about 30 working days. After the client checks the goods and pays the balance of 70% of the total contract value, we will deliver the goods at the time agreed by both parties.

5. Installation and commissioning

We will send videos and drawings for installation guidance. The seller can also send an engineer to the destination country to guide the installation and debugging, while our engineers are responsible for training the buyer's operators; The buyer should be responsible for our engineers' round trip airfare, visa costs, food and accommodation, and personal safety. And the buyer must supply one Chinese translator for our engineers. And the buyer must pay a salary of 100 US dollars per day to our engineer.

6. Our products are constantly updated, if there is any data discrepancy, please refer to the actual product.