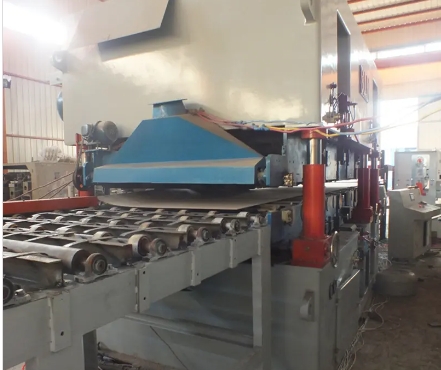

Plywood sanding machines SH13D [SH16D]

Used for preliminary calibration of material thickness and simultaneously double-sided sanding of wood-based panel materials. Can be used for sanding chipboard, MDF, OSB, plywood, etc.

Product benefits

1. The machine adopts advanced photoelectric technology and information management technology, combined with specially made thick thickness confirmation roller and high power electric machine, which can improve the working precision and quality of the panel.

2. The machine has humanistic control function. It can automatically confirm the thickness and control it with the program, which can make the operation more convenient.

3. Intricate intersection and arrangement of vertical grinding discs to prevent leakage from grooves. Thanks to the quick-change couplings, the sand strips can be easily changed.

4. Adopting the principle of centrifugal motion, the time of rust removal, polishing and deburring is reduced, and the efficiency is improved by 6-8 times.

5. No slipping during use, more friction. One wears and the other can continue to work.

6. The transport platform is made of marble, which has higher hardness and is not deformable.

7. Pure copper core motor, safe and durable.

8. Effectively filters water vapor in the air, prolongs the service life of pneumatic components and makes operation more stable.

Model |

SH13D(Two heads) |

Max.working width |

1300mm |

Min. grinding length |

780mm |

Sanding belt size |

1300*2500 mm |

Working thickness |

2.5-50mm |

Conveyor speed |

6-38m/min |

general power |

72.12 kW |

Feed rate |

20-50m/min |

dimensions |

2100*2100*2100 mm |

Weight |

3300 kg |

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After-sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.