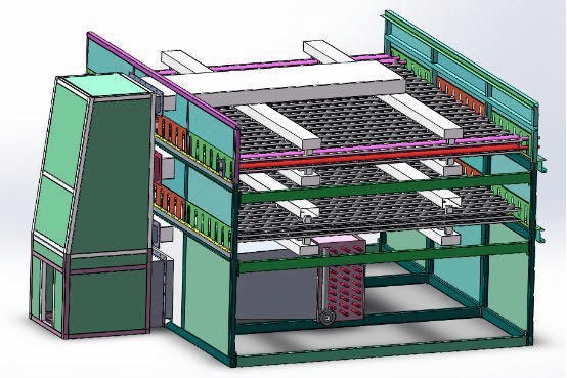

2 Tier Roller Veneer Dryer

Roller dryers are characterized by high productivity. The veneer sheets in the chamber are moved using paired rollers (one of the pair is driven, the second is pressed).

Space saving: Thanks to the ability to place veneer on two levels, the two-tier dryer takes up less space on the production line. This is especially useful in the case of limited production areas.

2 Tier Roller Veneer Dryer

Veneer dryer is one of the main equipment in the production process of veneer and plywood, and veneer drying technology directly affects the quality of plywood products.

Veneer dryer equipped automatic electrical control and frequency conversion system , which can automatically adjust the transfer speed and temperature according to the veneer thickness and moisture content to achieve the perfect drying effect. Equipped with automatic veneer feeding device and automatic

collection system, which not only increases drying efficiency, but also significantly saves labor costs.

Shine Company owns patent technology of air circulation and heat exchange system. Heat exchanger Shine

uses gradual heat transfer , and the characteristics of each heat exchanger section are different, the hot air in the heat exchanger fan is evenly supplied to the veneer.

Shine veneer dryer saves 38% energy . The hot air fan and cold air fan of the dryer use the latest axial fan, which reduces energy consumption and the overall power of the entire dryer decreases by 38% , which ensures minimal operating costs.

High quality videos

Rollers with a diameter of 89 mm, wall thickness 2.75 mm. Roller interval 180 mm.

Specifications

Model |

44+4 2 floors with boiler Width 3.0m |

52+4 2 floors with boiler Width 3.75m |

Working width |

3 m |

3.75 m |

Dryer temperature, ℃ |

140-200 |

140-200 |

Roller material |

Steel pipe Q235B, φ89 |

Steel pipe Q235B, φ89 |

Heating zones |

44 m |

52 m |

Cooling zone |

4 m |

4 m |

Initial humidity |

60-80% |

60-80% |

Final humidity |

10% +/-2 |

10% +/-2 |

Performance |

2-2.5m³/h |

3-3.5 m³/h |

Feed rate |

5-22m/min |

5-22m/min |

Heating fans power |

5.5kW*11 |

5.5kW*13 |

Cooling fan power |

5.5kW*1 |

5.5kW*1 |

Conveyor power |

7.5kW*2 |

7.5kW*2 |

Exhaust fan |

11 kW*2 |

15kW*2 |

general power |

103kW |

122 kW |

Electricity consumption |

67 kW/h |

80 kW/h |

Wood chip consumption |

8-10 tons/day |

15-17 tons/day |

Number of staff |

5-7 people/cm |

5-7 person/cm |

Cooling chamber

For dryers with a capacity of over 4 m 3 / h, the cooling chamber is separate, so that the veneer at the exit is not hot and is immediately suitable for further processing.

Saw

Product packaging

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.