Roller dryer for veneer

The veneer roller dryer is designed for drying veneer with a thickness of 0.8 to 8 mm.

The coolant is thermal oil, heating elements, steam.

Veneer drying capacity 0.5 – 8 m³/hour

Our veneer roller dryer is compact and easy to install even indoors. Each dryer section undergoes factory testing with comprehensive quality checks.

With the help of the upper and lower drive rollers, the veneer moves between the panels.

The speed of movement is regulated by a frequency converter; depending on the thickness of the veneer being dried, the feed speed is determined.

The drying process is fully automated. Parameters are adjusted from the control panel: speed of movement of the product, temperature in the product, temperature on the panels.

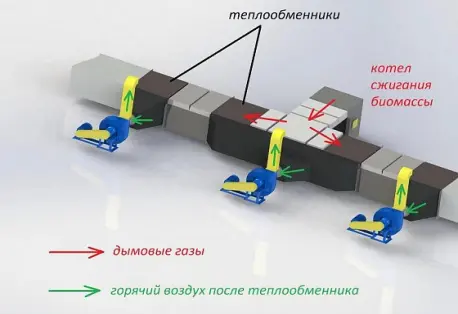

At the customer's discretion, the following is installed to heat the coolant during installation:

1. Gas boiler

2. Wood boiler

3. Pellet boiler

Veneer dryer parameters

Model |

44+4 2 floors with boiler Width 3.0m |

52+4 2 floors with boiler Width 3.75m |

32+4 4 floors with boiler Width 3.0m |

44+4 4 floors with boiler Width 4.5m |

Working width |

3 m |

3.75 m |

3 m |

4.5 m |

Dryer temperature, ℃ |

140-200 |

140-200 |

140-200 |

140-200 |

Roller material |

Steel pipe Q235B, φ89 |

Steel pipe Q235B, φ89 |

Steel pipe Q235B, φ102 |

Steel pipe Q235B, φ102 |

Heating zones |

44 m |

52 m |

32 m |

44 m |

Cooling zone |

4 m |

4 m |

4 m |

4 m |

Initial humidity |

60-80% |

60-80% |

60-80% |

60-80% |

Final humidity |

10% +/-2 |

10% +/-2 |

10% +/-2 |

10% +/-2 |

Performance |

2-2.5m³/h |

3-3.5 m³/h |

3.5-4 m³/h |

7-8m³/h |

Feed rate |

5-22m/min |

5-22m/min |

5-22m/min |

5-22m/min |

Heating fans power |

5.5kW*11 |

5.5kW*13 |

4kW*32 |

4kW*44 |

Cooling fan power |

5.5kW*1 |

5.5kW*1 |

4kW*4 |

4kW*4 |

Conveyor power |

7.5kW*2 |

7.5kW*2 |

5.5kW*4 |

7.5kW*4 |

Exhaust fan |

11 kW*2 |

15kW*2 |

15kW*2 |

15kW*2 |

general power |

103kW |

122 kW |

196 kW |

252 kW |

Electricity consumption |

67 kW/h |

80 kW/h |

128 kW/h |

164 kW/h |

Wood chip consumption |

8-10 tons/day |

15-17 tons/day |

17-19 tons/day |

22-25 tons/day |

Number of staff |

5-7 people/cm |

5-7 person/cm |

5-7 person/cm |

6-8 person/cm |

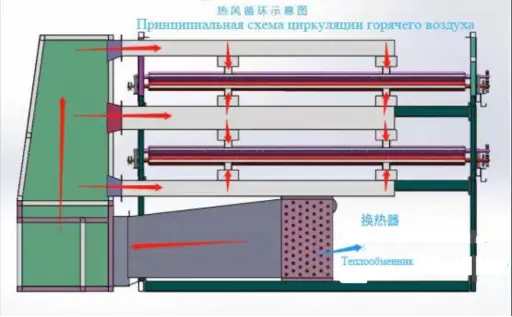

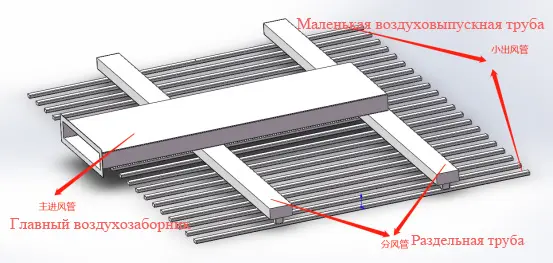

Principle of operation

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.