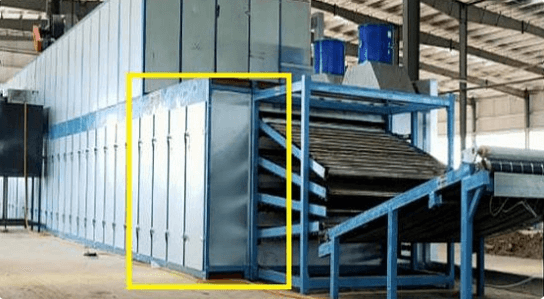

4 Tier Roller Veneer Dryer

4 Tier Roller Veneer Dryer uses a low-power fan, which significantly reduces the power of all equipment and saves consumers on energy costs.

The fan was custom made from a professional manufacturer, with copper wire.

Save space.

4 Tier Roller Veneer Dryer usually combined with fully automatic transmission and collection equipment.

The device looks more elegant and beautiful.

4 Tier Roller Veneer Dryer

A veneer dryer usually consists of several sections or compartments that are connected in one common body. The process begins by loading freshly cut veneer into the dryer.

Then the fan turns on, which creates air circulation inside the compartment. Fans supply hot air, heated by heating elements, into the compartment. The air flow is distributed evenly over the veneer surface.

During the drying process, the humidity process itself is monitored using sensors that can measure the moisture level inside the compartment. Controllers adjust the heat input and drying time to achieve the optimal moisture level for the veneer at the end of the process.

Drying duration and settings depend on various factors, such as the type of wood, the initial moisture level of the veneer, and the desired final moisture level.

Veneer drying is a process whereby veneer, which initially contains high moisture content, is dried to an optimal level so that it can be used in furniture or surface finishing.

This process of drying veneer is very important, since moistened veneer can show undesirable properties and become deformed. In addition, furniture made from damp veneer is more likely to deteriorate over time.

Veneer dryer is an important equipment for plywood production. It is used to dry veneer - thin layers of wood that serve as the basis for making plywood.

Firstly, a veneer dryer allows you to remove excess moisture contained in the wood. This is important because veneers with a high moisture content can cause the plywood sheets to warp during further processing. Drying the veneer also improves its resistance to moisture, which makes the plywood more durable and reliable.

Secondly, a veneer dryer allows you to achieve optimal moisture content for the veneer before gluing it. This is important because veneers that have the wrong moisture content can result in poor quality plywood and the need for rework or even replacement.

Thirdly, the veneer dryer helps improve the productivity and efficiency of the plywood production process. By properly drying veneer, you can reduce the time spent on plywood production, improve the quality of the finished product and increase its competitiveness in the market.

Specifications

Model |

32+4 4 floors with boiler Width 3.0m |

44+4 4 floors with boiler Width 4.5m |

Working width |

3 m |

4.5 m |

Dryer temperature, ℃ |

140-200 |

140-200 |

Roller material |

Steel pipe Q235B, φ102 |

Steel pipe Q235B, φ102 |

Heating zones |

32 m |

44 m |

Cooling zone |

4 m |

4 m |

Initial humidity |

60-80% |

60-80% |

Final humidity |

10% +/-2 |

10% +/-2 |

Performance |

3.5-4 m³/h |

7-8m³/h |

Feed rate |

5-22m/min |

5-22m/min |

Heating fans power |

4kW*32 |

4kW*44 |

Cooling fan power |

4kW*4 |

4kW*4 |

Conveyor power |

5.5kW*4 |

7.5kW*4 |

Exhaust fan |

15kW*2 |

15kW*2 |

general power |

196 kW |

252 kW |

Electricity consumption |

128 kW/h |

164 kW/h |

Wood chip consumption |

17-19 tons/day |

22-25 tons/day |

Number of staff |

5-7 person/cm |

6-8 person/cm |

The dryer has warm and cold wind zones.

Cooling chamber

For dryers with a capacity of over 4 m 3 / h, the cooling chamber is separate, so that the veneer at the exit is not hot and is immediately suitable for further processing.

High quality videos

Rollers with a diameter of 102 mm, wall thickness 2.5 mm. Roller interval 330 mm.

Saw

Certification

Shine Institute

Our services

Pre-sales services:

1.Free consultation on the entire line of equipment for plywood production

2.Offer reasonable plan and free design according to customers' special requirements to help select equipment.

3.Welcome to our factory

Services during sales:

1. Inspect the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3.Training of first line operators.

After sales services:

1.Online service 24 hours a day

2.Providing videos with installation and configuration of equipment

3.Providing technical support (Technical phone: +8619653165764). A visit to the client service is available.