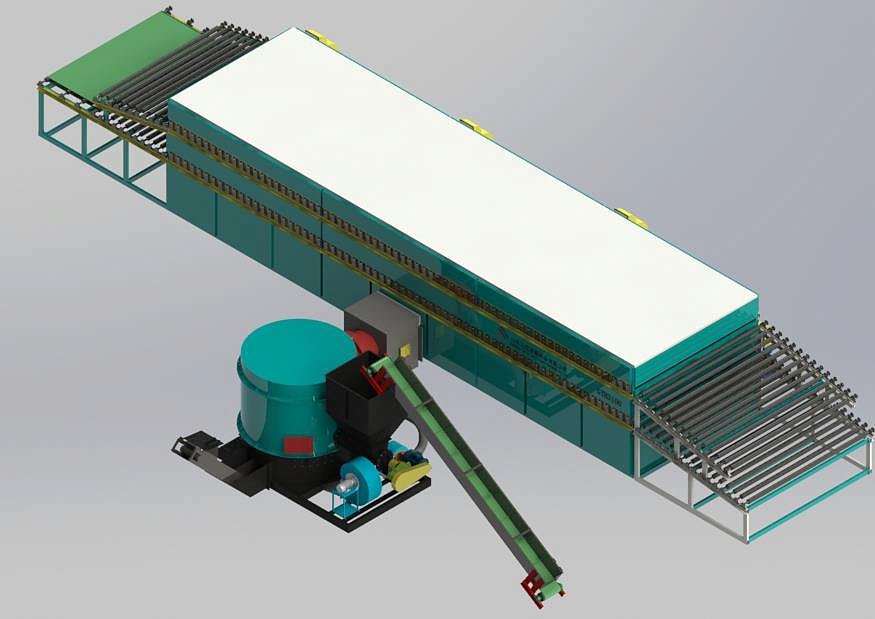

Roll dryer for veneer

Advantages:

*Automatic temperature and drying speed control system.

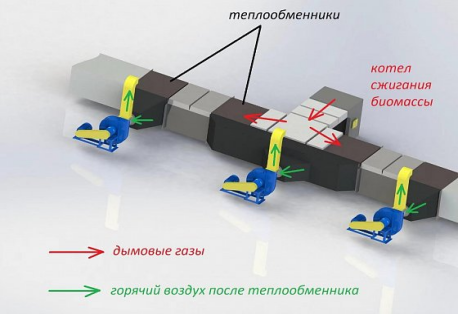

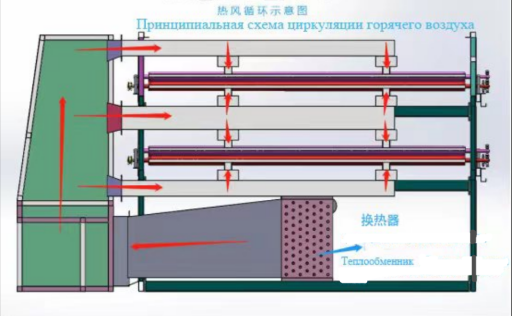

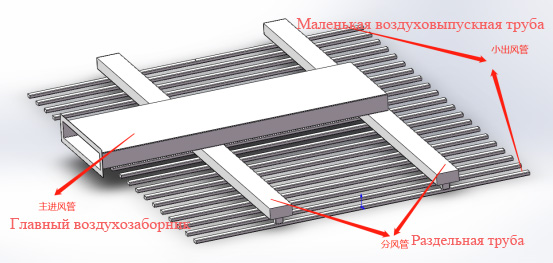

*Combustion and heat exchange system with high efficiency and low drying cost.

*The control cabinet has an automatic temperature and speed control system.

*After drying, the veneer becomes smooth, without cracks, wrinkles and ripples at the ends. Doesn't get dark.

*Bearings and bushings are resistant to high temperatures and do not require maintenance and repair.

Veneer dryer

Shine veneer dryer has high performance, energy efficiency, low drying cost and perfect drying effect. Some of the outstanding features include our patented Biomass Burner, Heat Exchanger and Automatic Feeder. The plywood veneer drying machine has minimal electricity and fuel consumption, maximum productivity and quality, and is also energy efficient. The veneer is fed into the dryer and moved through the dryers by running rollers, and at the same time, hot air is blown on the surface and back of the veneer to achieve the drying effect. We can provide various types of veneer drying machine to meet the special needs of users of capacity.

Working principle of veneer roller dryer

The veneer roller dryer is driven by a chain that drives the top and bottom rolls, with the top roll pushing the plywood to move. For heating, a biomass boiler is used, which burns sawdust, wood waste and other materials at high temperature. The materials are boiled and fluidized in the burner, providing thermal energy for the dryer. For processing surface plywood and long core plywood, this dryer can avoid plywood bursting, which improves plywood utilization rate and productivity.

Patented Product - Biomass Burner

The biomass burner is Shine's patented product. It can burn all kinds of waste wood directly, which greatly reduces the cost of drying. Compared with steam or oil heated veneer dryer, the drying cost is greatly reduced.

Veneer dryer parameters

| Model | 44+4 2 floors with boiler Width 3.0m | 52+4 2 floors with boiler Width 3.75m | 32+4 4 floors with boiler Width 3.0m | 44+4 4 floors with boiler Shir 4.5m |

| Working width | 3 m | 3.75 m | 3 m | 4.5 m |

| Temperature in the dryer, ℃ | 140-200 | 140-200 | 140-200 | 140-200 |

| Roller material | Steel pipe Q235B, φ89 | Steel pipe Q235B, φ89 | Steel pipe Q235B, φ102 | Steel pipe Q235B, φ102 |

| Heating zones | 44 m |

52 m | 32 m | 44 m |

| Cooling zone | 4 m | 4 m | 4 m | 4 m |

| Initial humidity | 60-80% |

60-80% | 60-80% | 60-80% |

| End Moisture | 10% +/-2 | 10% +/-2 | 10% +/-2 | 10% +/-2 |

| Performance | 2-2.5 m³/h | 3-3.5 m³/h | 3.5-4m³/h | 7-8m³/h |

| Feed rate | 5-22m/min |

5-22m/min | 5-22m/min | 5-22m/min |

| Heating fan power | 5.5kW*11 |

5.5kW*13 | 4kW*32 |

4kW*44 |

| Cooling fan power | 5.5kW*1 | 5.5kW*1 | 4kW*4 | 4kW*4 |

| Conveyor power | 7.5kW*2 | 7.5kW*2 | 5.5kW*4 | 7.5kW*4 |

| Exhaust fan | 11 kW*2 | 15kW*2 | 15kW*2 | 15kW*2 |

| general power | 103kW | 122 kW | 196 kW | 252 kW |

| Electricity consumption | 67 kW/h | 80 kW/h | 128 kW/h | 164 kW/h |

| Chip consumption | 8-10 tons/day | 15-17 tons/day | 17-19 tons/day | 22-25 tons/day |

| Number of staff | 5-7 persons/cm | 5-7 person/cm | 5-7 person/cm | 6-8 person/cm |

Principle of operation

Certification

Zavod Shine

Our services

Pre-sales services:

1. Free consultation on the entire line of plywood production equipment

2.Offer reasonable plan and free design according to customers' special requirements to help choose equipment.

3.Welcome to our factory

Services during sales:

1. Inspection of the machine before leaving the factory.

2.Installation and configuration of equipment abroad

3. Training of first line operators.

After-sales services:

1. Online service 24 hours a day

2.Providing a video with the installation and configuration of equipment

3. Providing technical support (Technical phone: +8619653165764 ). Service of departure to the client is possible.